Society

Safety Education and Training

NOF Group RC Education and Training

The NOF Group focus on RC education as a way of deepening understanding of RC among its employees. In fiscal 2024, a total of 46,420 people participated in a total of 35,791 hours of RC-related education and training.

Education on the handling of organic peroxides

(PT.NOF MAS CHEMICAL INDUSTRIES)

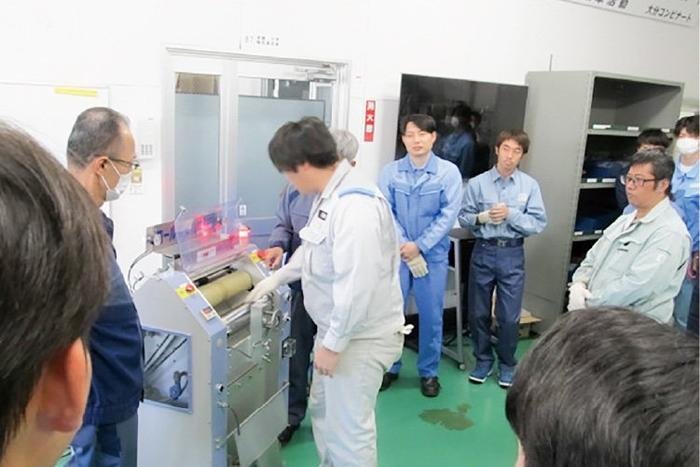

Presentation of activities with all employees participating

(Oita Works)

RC education and training (FY2024)[Covered organizations:NOF Group]

| Field | Total number of participants (persons) |

Total number of hours (hours) |

|---|---|---|

| All aspects of RC | 4,622 | 2,858 |

| Labor safety | 32,825 | 26,226 |

| Environmental safety | 3,276 | 953 |

| Product safety | 4,595 | 2,249 |

| Plant safety | 576 | 390 |

| Transportation safety | 526 | 3,115 |

| Total | 46,420 | 35,791 |

Hands-On and Experience-Based Education

The NOF Group has adopted hands-on and experience-based safety education as a training step for preventing occupational accidents. Such experience of danger in a simulated environment is expected to help improve their sensitivity to danger and raise awareness of safety.

We had mainly offered external educational programs, but currently focus on more field-oriented education through experience-based education.

Experience-based hazard education (Amagasaki Plant)

Hands-on practical safety training (Oita Plant)

Red Cross first-aid training course (Oita Works)

Individual “safe practice declaration” Activities

Domestic Group companies

Based on the results of analysis into the causes of occupational accidents that occurred in fiscal 2011, we determined that raising safety awareness would be crucial in eliminating occupational accidents caused by human factors, such as a lack of awareness of danger and carelessness. Since fiscal 2012, we have been implementing “individual ‘safe practice declaration’ activities,” that is, individuals setting of action targets for occupational safety and taking action to achieve them. This system is implemented in a way considered suitable for each plant, such as disclosing safe practice declarations of all personnel, including those at cooperating companies, on a bulletin board, etc.

BCP Training and Education

NOF continuously holds basic training on disaster response measures for earthquakes, fires, infectious diseases, and other disasters with the aim of improving the effectiveness of its business continuity plan (BCP). Specifically, we inform employees of action standards based on manuals for earthquake disaster prevention and infectious disease control, along with conducting emergency contact drills using a safety confirmation system, leakage prevention drills, and initial response firefighting training.

In fiscal 2024, we conducted a company-wide joint BCP drill anticipating complex risks, including cyberattacks on overseas bases and safety assurance of employees overseas. Through this training, we strengthened the information sharing system between emergency headquarters and each location, and verified the effectiveness of the BCP.

We will continue improving our company-wide response capabilities through BCP education and training.

Company-wide joint BCP training

Company-wide joint BCP training

Disaster Prevention Drills

The NOF Group manufactures hazardous materials, including organic peroxides, and explosives. Considering that minimizing damage both inside and outside the company in the event of an accident is of the utmost importance, we actively conduct disaster prevention drills. In particular, we regularly conduct joint disaster prevention drills together with local organizations as part of efforts to strengthen disaster countermeasures.

We also actively participate in local firefighting skills competitions, etc. to improve firefighting skills and demonstrate our high level of safety awareness.

Comprehensive disaster prevention drill

(Kawasaki Works)

High-pressure gas disaster prevention drill

(Amagasaki Plant)

Initial response firefighting training

(Oita Works)

Integrated disaster prevention drill for industrial complexes

(Oita Works)

Joint disaster prevention drill

(NiGK Corporation)

Fire prevention association firefighting skills competition

(YUKA SANGYO CO., LTD.)

Disaster prevention drill

(Changshu NOF Chemical Co., Ltd.)

Firefighting training

(PT.NOF MAS CHEMICAL INDUSTRIES)

Awards for Safety Activities

The NOF Group has received various awards in recognition of its daily safety activities and consistently accident-free operations at facilities that handle hazardous materials, etc.

Amagasaki Plant, Kawasaki Works, and YUKA SANGYO CO., LTD. received awards in recognition of their initiatives related to hazardous materials.

JAPEX Corp. received an award for its achievements related to explosives safety management.

NiGK Corporation received an award for their excellent performance at a firefighting skills competition.

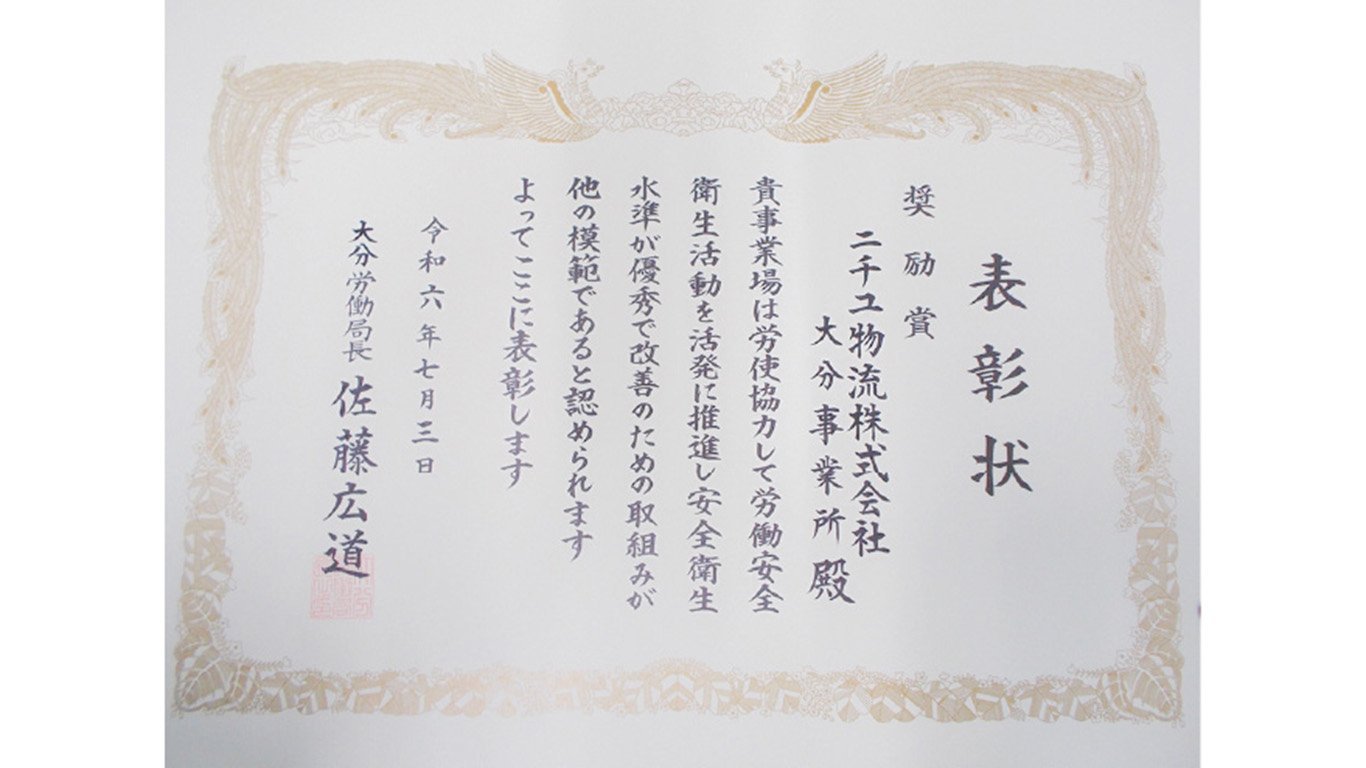

Nippon Koki Co., Ltd. received an award in recognition of its safe driving efforts, while NOF METAL COATINGS ASIA PACIFIC CO., LTD. and NICHIYU LOGISTICS CO., LTD. received awards in recognition of their health and safety-related initiatives.

Encouraged by these awards, we will continue making all-out effort into safety activities and accident prevention, and further promote safety management.

Record of awards for safety activities

| Works / plants | Awarding date | Name |

|---|---|---|

| Amagasaki Plant | 2024/6/12 | Received the award for excellent boiler engineers from the Hyogo branch of the Japan Boiler Association |

| 2024/6/13 | Received the award for excellent high-pressure gas safety managers from the Hyogo High-Pressure Gas Safety Organization | |

| 2024/11/15 | Received the Chairperson’s Award for excellent boiler welders from the Japan Boiler Association | |

| Kawasaki Works | 2025/1/9 | Received the award for long-term continual service as an excellent hazardous materials safety supervisor from the Rinko Factory Firefighting Council |

| Nippon Koki Co., Ltd. | 2025/2/21 | Received an award from the Hokkaido Safe Driving Managers Association (achieving zero accidents resulting in death or injury) |

| NiGK Corporation | 2024/5/23 | Received the excellent long-time service employee award from the Saitama Prefectural Explosive Safety Association |

| 2024/10/16 | Kawagoe District Fire Dept. in-house firefighting drill competition (winning in outdoor fire hydrant event) |

|

| YUKA SANGYO CO., LTD. | 2024/5/9 | Received an award from the Chairperson of the Federation of Associations for Safety of Hazardous Materials in Kanto-Koshinetsu area |

| NOF METAL COATINGS ASIA PACIFIC CO., LTD. | 2025/3/10 | Recognized as a 2025 Outstanding Organization of KENKO Investment for Health (SME category) |

| JAPEX Corp. | 2024/5/30 | Received a Certificate of Appreciation from the Tokyo Explosives Safety Association (for long-term service of the Association Director and Registered Instructors) |

| NICHIYU LOGISTICS CO., LTD. | 2024/7/3 | Received the award for safety and health excellence at business sites from the Oita Labour Bureau |

Received an award from the Chairperson of the Federation

of Associations for Safety of Hazardous Materials

in the Kanto-Koshinetsu area for services to improving facilities

and safety management

(YUKA SANGYO CO., LTD.)

Received the award for safety and health

from the Oita Labour Bureau

(NICHIYU LOGISTICS CO., LTD.)