Environment

RC Management

Policy

Management Policy Regarding Responsible Care

For a chemical company to live together with society as one of its vitally important members, all of its business activities have to seek harmony with the social and natural environments and be recognized, appreciated, and accepted by society. With this fundamental awareness in mind, the NOF Group has set forth its Management Policy Regarding Responsible Care as a set of norms to be faithfully observed by every officer and employee of the Group with a view to winning even greater trust from society.

Furthermore, NOF became a signatory of the Responsible Care Global Charter proposed by the International Council of Chemical Associations in 2014, along with declaring its support of the Charter and its commitment to practice RC activities both in Japan and overseas.

Management Policy Regarding Responsible Care

The NOF Group is dedicated to protecting the safety and health of customers, the public, and employees, as well as the environment, ecosystems, and resources. For this purpose, based on the principles of Responsible Care, NOF, its affiliates, and all executives and employees observe the following management policies on safety concerning the five areas of the environment, products, plants, transportation, and labor.

All officers and employees of NOF and affiliate companies shall

- work to minimize the impact of products on the environment, safety, and health, which covers every aspect of products, from their development and manufacture through retail, use, and disposal,

- based on appropriate self-management and close collaboration with other business units,

- by making sure to conduct highly reliable safety checks and adhere to all laws and regulations,

- while also being fully aware of safety issues involving the social and natural environments.

(Amended April 2023)

Toward harmony with nature and society

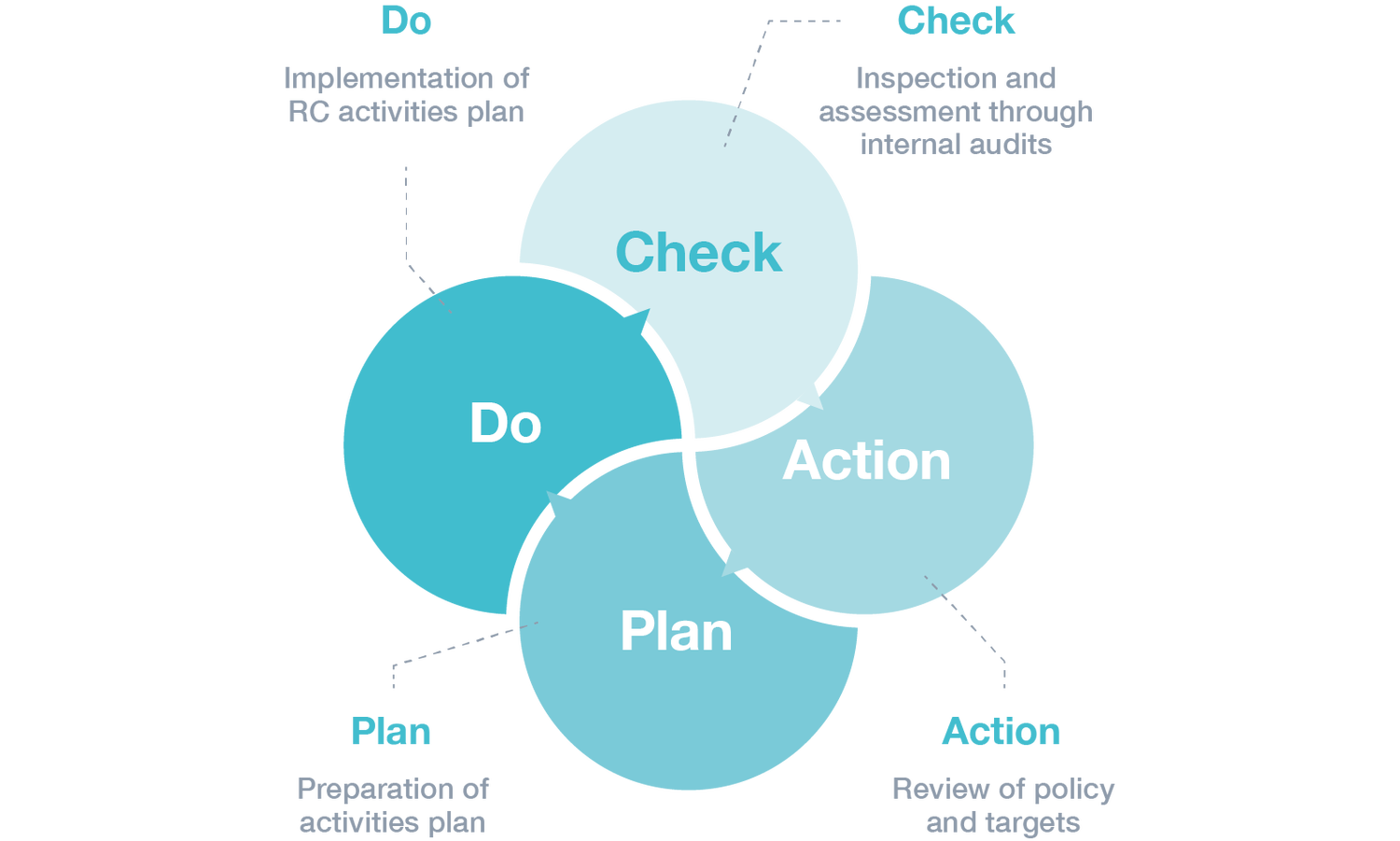

Based on our management policy, we are working to level up the Five Components of Safety (environment, plants, products, labor, and transportation) through the Responsible Care activities we are working on by ensuring that the PDCA cycle is followed every year.

Immediate challenges in terms of environmental safety include responding to climate change and conserving biodiversity; for plant safety, stable operations; for product safety, providing safety information on chemical substances; for labor safety, protecting employees; and for transportation safety, safe deliveries.

In addition, we recognize that the chemical manufacturing industry is energy-intensive, and will work to reduce greenhouse gas emissions and effectively use water resources. Furthermore, with an awareness that emergencies have an impact on ensuring the safety of our employees and surrounding communities, we will strive in our aim to achieve zero accidents.

We will promote Responsible Care activities across the entire Group, achieve harmony with nature and society, and deliver safety and security to everyone.

Director and Executive Operating Officer General Manager, Corporate Technical Division

Kazuyoshi Yamauchi

Initiatives to Ensure the Five Components of Safety

The NOF Group is working on various initiatives to ensure the Five Components of Safety. The Group classifies its RC activities into “Five Components of Safety” comprising environmental safety, plant safety, product safety, labor safety, and transportation safety. Every year, we set RC activity targets, key issues, and implementation items, which are then applied to specific measures for each works, plant, and Group company. These activities have been implemented since 1995. In addition, “dialogue with society,” including information disclosure and exchanges with local communities, has been added to the Five Components of Safety as a theme of the activities.

Promotion System

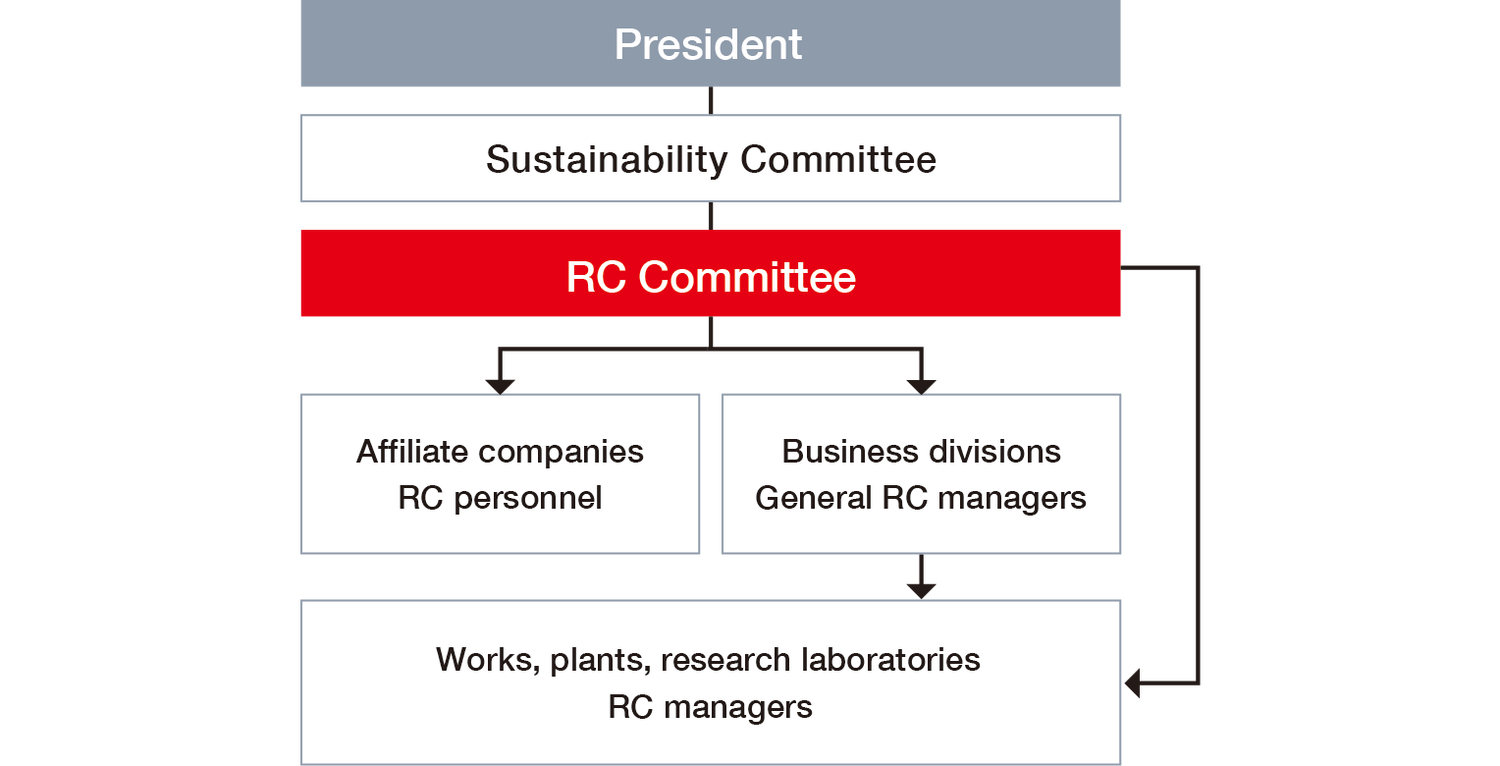

RC promoting organization

The RC Committee, chaired by an Operating Officer appointed by the President (Kazuyoshi Yamauchi, General Manager of the Corporate Technical Division (concurrently Director and Executive Operating Officer)), comprises business division managers and corporate division managers.

In order to ensure that decisions on RC activities made by the RC Committee are thoroughly disseminated as Group policies in a timely manner, managers and staff in charge are assigned to business divisions, plants, research laboratories, and affiliate companies to ensure the concrete rollout of RC targets.

RC promoting organization diagram

Flowchart of development of RC activities

RC activities are being developed by ensuring that the PDCA cycle is followed in an effort to “spiral up” the activities.

Internal auditing (RC audits)

Status of internal auditing (RC audits)

The NOF Group carries out RC auditing every year to ensure the effectiveness of RC activities. We have been continually conducting RC auditing at target domestic and overseas works, plants, and subsidiaries since fiscal 1998. In fiscal 2024, we conducted audits across the entire Group with the priority theme set as “legal compliance.” We checked the progress of RC activity targets and the levels of activities related to the Five Components of Safety at all works and plants, and encouraged them to make improvements.

In addition, we conduct on-site and written audits of all business works and plants to strengthen chemical substance management. In addition to reporting on new chemical substances (actual result in FY2024: 494), we confirmed the status of compliance with laws and regulations concerning chemical substance management and confirmed the status of improvements to items indicated in the FY2023 audit. Through this, we worked to improve the level of chemical substance management. We follow up on the progress of responding to all items indicated in the audit to ensure that all remedial measures are taken.

Priority audit themes for the past five years are listed on the below.

Implementation status of RC auditing

| Fiscal year | Priority theme in audit |

|---|---|

| FY2020 |

|

| FY2021 |

|

| FY2022 |

|

| FY2023 |

|

| FY2024 |

|

EMS

The NOF Group is promoting the acquisition of certification by competent external bodies as a means of improving transparency and objectivity of environmental safety activities.

Development status of EMS*1 (Environmental management systems)

All of NOF’s works and plants with manufacturing divisions have acquired ISO 14001 certification, and we are systematically implementing environmental improvement activities in consideration of the particulars of business and local characteristics. Six consolidated subsidiaries of NOF have acquired ISO 14001 certification. Also, NICHIYU LOGISTICS CO., LTD. has obtained Green Management certification from the Foundation for Promoting Personal Mobility and Ecological Transportation.

Rate of acquisition of ISO14001 certification (production volume basis*2)

- FY2023 environmental certification:93%[Covered organizations:Domestic Group], 90%[Covered organizations:NOF Group]

- FY2024 environmental certification:94%[Covered organizations:Domestic Group], 91%[Covered organizations:NOF Group]

NOF

| Works and plants | Environmental management systems | Certification number | Latest recertification date |

|---|---|---|---|

| Kawasaki Works | ISO14001 | JP025987V1.0 | March 2025 |

| Aichi Works | ISO14001 | JP023236 | January 2023 |

| Amagasaki Plant | ISO14001 | 4705737-2A | September 2022 |

| Oita Plant | ISO14001 | JP024408 | January 2024 |

Group companies

| Name | Environmental management systems | Certification number | Latest recertification date |

|---|---|---|---|

| Nippon Koki Co., Ltd. Shirakawa Plant |

ISO14001 | JSAE741 | December 2024 |

| NOF METAL COATINGS ASIA PACIFIC CO., LTD. |

ISO14001 | JP025639 | November 2024 |

| Changshu NOF Chemical Co., Ltd. | ISO14001 | CN20/21620 | January 2024 |

| NOF METAL COATINGS EUROPE S.A. |

ISO14001 | N°2000/14320.7 | December 2023 |

| NOF METAL COATINGS EUROPE N.V. |

ISO14001 | 10477422 | October 2024 |

| NOF METAL COATINGS SOUTH AMERICA IND. E COM.LTDA. |

ISO14001 | BR040178 | December 2023 |

- Acronym for Environmental Management Systems. A management system comprising a framework for an organization to formulate, implement, review, and maintain its environmental policy; and encompassing planning activities, responsibilities, practices, processes, and management resources.

- Production volume basis: Based on the total production volume of works, plants, and affiliates with production divisions (4 non-consolidated, 7 domestic affiliates, and 6 overseas affiliates).