Safety Management

- TOP

- Sustainability

- Society

- Safety Management

RC* Education

RC Education of the NOF Group

To enable all the employees of the NOF Group to deepen their understanding of RC, emphatic efforts are put into RC education. In fiscal 2022, a total of 53,066 people participated in and received RC-related education and training for a total of some 41,000 hours.

* RC: Acronym for "Responsible Care.

| Field | Total number of participants | Total time (in hours) |

|---|---|---|

| RC | 4,353 | 3,675 |

| Laber Safety | 32,803 | 25,355 |

| Environmental Safety | 4,406 | 2,630 |

| Product safety | 7,138 | 6,579 |

| Plant Safety | 3,137 | 1,426 |

| Product safety | 1,229 | 1,263 |

| Total | 53,066 | 40,949 |

Lifesaving first aid training

(Advanced Technology Research Laboratory)

Spill prevention drill

(Amagasaki Plant)

Safety education by try-and-sense method

The NOF Group has introduced safety education by a try-and-sense method, which aims at labor accident prevention by having the trainees gain a simulated experience of danger with a view to making the employees more sensitive to potential danger and more conscious of safety.

We offered educational programs mainly for external entities so far, and we are currently working on more field-oriented education for our employees through the introduction of education by experience

Experience of becoming entangled in

rotating equipment (Amagasaki Plant)

Experience of high-elevation falls

(Amagasaki Plant)

Each individual’s “safe practice declaration” activities (Domestic Group)

The need for enhanced safety awareness to eliminate labor accidents was recognized in fiscal 2011, as a result of the frequent occurrence of such accidents attributable to human factors including the lack of a sense of danger and carelessness. Since fiscal 2012, we have been implementing “each individual’s ‘safe practice declaration’ activities,” namely the setting of action targets for labor safety by each individual person and taking action to achieve the targets. This system is implemented in a way considered suitable for each plant, such as safe practice declarations of individuals, including the personnel of cooperating companies at the site, being made open to everybody by posting on a bulletin board.

BCP training and education

We conducted our first-ever company-wide joint drill with the cooperation of all production sites in Japan, based on the assumption of extensive damage from a nationwide earthquake. The drill focused on establishing a smooth information-sharing and cooperation system between the Emergency Headquarters at the Head Office and each production site to confirm and improve the effectiveness of the BCP that has been formulated.

We are also actively expanding our BCP through ongoing efforts regarding the development of the BCP and education in preparation for emergencies such as infectious disease outbreaks and cyberattacks.

Company-wide joint drill (Head Office)

Company-wide joint drill (Emergency

Headquarters at the Head Office)

Company-wide joint drill

(online: Kawasaki Works, Aichi Works,

Amagasaki Plant, Oita Plant)

Disaster prevention drills

The NOF Group manufactures hazardous materials and explosives, including organic peroxides. We consider minimizing internal and external damage in the event of a disaster to be of the utmost importance, and actively conduct disaster prevention drills. In particular, we regularly conduct joint disaster prevention drills with local organizations to strengthen disaster countermeasures in cooperation with local communities.

We also actively participate in local firefighting technique competitions to improve firefighting skills and appeal to communities by demonstrating our high level of safety awareness.

Joint disaster prevention drill with Taketoyo Town and neighboring fire departments

(Aichi Works)

Joint comprehensive disaster prevention

drill with the Chidori District Disaster

Prevention Association (Kawasaki Works)

High-elevation rescue drill (Amagasaki Plant)

Injured person transportation drill

(HOKKAIDO NOF CORPORATION)

Fire extinguisher training (MCNA)

Annual Self-Defence Firefigting Maneuvers Competition(NIGK Corporation)

Communities and cooperation

In providing against accidents that might happen, close collaboration with local disaster-fighting organizations is indispensable. The NOF Group is actively trying to create opportunities to strengthen its disaster preparedness by engaging in joint drills with local organizations for damage prevention. Joint disaster-fighting drills and emergency support drills with neighboring companies are increasingly adapted to practical needs year after year. Large-scale drills have become frequent with the participation of local fire and police stations.

The Kawasaki Works entered into an agreement with the municipal government of Kawasaki to offer itself as a refugefacility against tsunami, and would open its general office building to general citizens seeking help. Besides these drills, individual works also participates in local disaster-fighting drills at the request of organizations they belong to.

Cooperation with crime prevention activities

Nippon Koki Co., Ltd. cooperated with the local Shirakawa Police Station’s "Dial 110 Day" event by exhibiting its crime prevention products and demonstrating the NET LAUNCHER.

Exhibit of the NET LAUNCHER

crime prevention device at

the Shirakawa Police Station’s

Cooperation for local events

In Kawagoe City, where NiGK Corporation is located, a local conference event was held to commemorate the 100th anniversary of the city’s establishment and to provide an opportunity to discuss how to create a better community. We provided humus from our plant to the “welfare market” at the event.

Exhibit at the welfare market of the event

commemorating the 100th anniversary of

Kawagoe City’s establishment

(NiGK Corporation)

Awards for safety activities

The NOF Group has received various awards in recognition of its daily safety activities and consistently disaster-free operations at facilities that handle hazardous materials.

The Kawasaki Works received an award from Kanagawa Prefecture recognizing its longstanding management of high-pressure gas.

HOKKAIDO NOF CORPORATION received an award from Bibai City recognizing its achievements in hazardous materials and explosives safety.

Nippon Koki Co., Ltd. received an award from the Japan Explosives Society, which highly evaluated its paper on the NET LAUNCHER crime prevention device.

NICHIYU LOGISTICS CO., LTD. received an award from Oita Prefecture for its consistently accident-free operations. Encouraged by these awards, we are determined to continue pursuing safety activities and accident prevention and will strive to further promote safety management.

Kanagawa Prefecture Industrial Safety

Award (Kawasaki Works)

Japan Explosives Society Technology Award

(Nippon Koki Co., Ltd.)

Prize in the Zero-Accident Certification

Program for SMEs

(NICHIYU LOGISTICS CO., LTD. (Oita))

Award from the Bibai City Association for

Safety Management of Hazardous

Materials(HOKKAIDO NOF CORPORATION)

Record of awards for safety activities

| Works/Plants | Date awarded | Name |

|---|---|---|

| Amagasaki Plant | 2022/6/7 | Received the award for excellent high-pressure gas safety manager by the Hyogo High-Pressure Gas Safety Organization |

| 2022/6/13 | Received the award for excellent boiler engineers by the Hyogo Branch of the Japan Boiler Association | |

| Aichi Works | 2022/4/21 | Handa association for safety hazardous materials Excellent Hazardous Materials Contorol Award |

| Kawasaki Works | 2022/6/24 | Kanagawa Prefecture Industrial Safety Award (for excellent high pressure gas production safety manager, etc.) |

| Nippon Koki Co., Ltd. | 2022/5/20 | Excellent Hazardous Materials Control Award, Shirakawa Area Fire and Disaster Prevention Association |

| 2022/5/24 | Japan Explosives Society Technology Award (achievements related to the advancement of explosive echnologies) | |

| 2022/12/14 | METI Minister’s Award for Excellent Explosives Security | |

| NiGK Corporation | 2022/5/30 | Saitama Prefectural Explosive Safety Association, Excellent Long Service Employee Award |

| HOKKAIDO NOF CORPORATION | 2022/6/1 | Bibai City Association for Safety Management of Hazardous Materials, Award for Employees’ Long-time Service |

| 2023/3/16 | Hokkaido Safe Driving Managers Association, award for excellent safe driving management office | |

| Showa Kinzoku Kogyo Co., Ltd. | 2022/12/2 | Chikusei Labor Standards Association, award for excellent workers |

| NOF METAL COATINGS ASIA PACIFIC CO., LTD. | 2023/3/8 | 2023 Certified Health & Productivity Management Outstanding Organizations Recognition Program (SME category) |

| NICHIYU LOGISTICS CO., LTD. | 2022/8/18 | Zero-Accident Certification Program for SMEs, Category 3: Bronze Prize |

Customer health and safety

Transportation safety

The NOF Group is promoting the reduction of the environmental load in transportation, while at the same time engaging in activities to ensure the safety of products in transport. The Group has always treated transportation safety with desirable care, as it handles a wide range of hazardous materials.

Forklift training session

(NICHIYU LOGISTICS CO., LTD.)

Forklift training session

(NICHIYU LOGISTICS CO., LTD.)

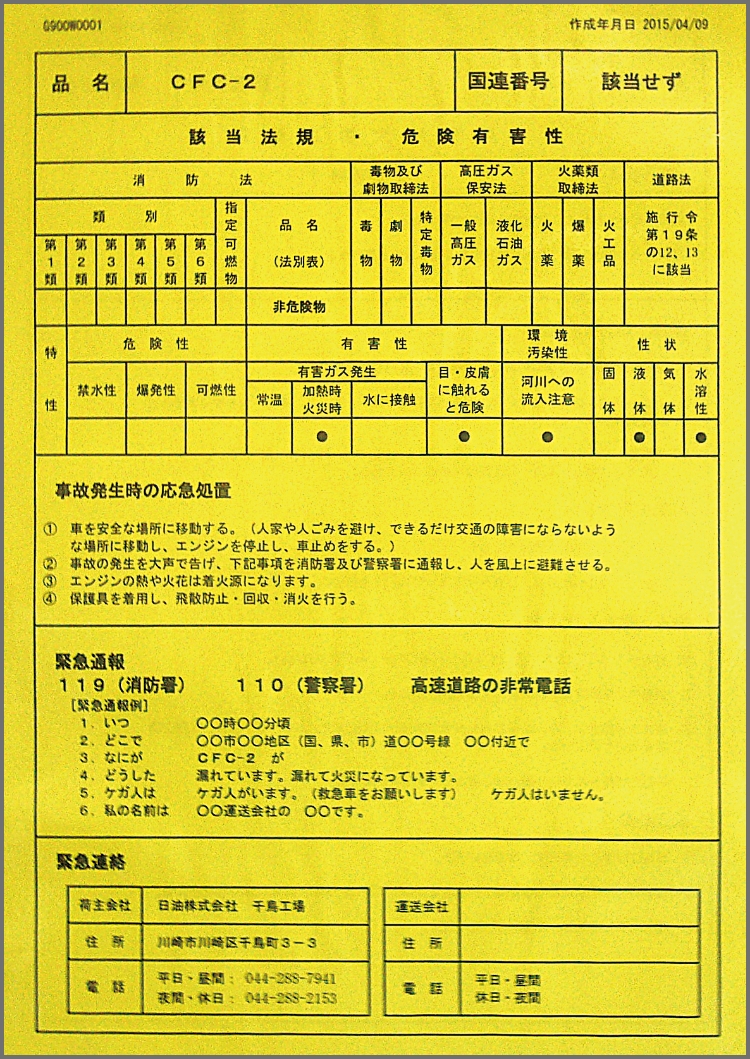

Yellow card

Should an accident occur during the transportation of chemical substances, it could have dire consequences on human life, the neighboring area, the cargo, and the road. The Yellow Card states the measures transport operators, the fire brigade, and the police should take as well as contact and notification information, in the event of such an accident. The NOF Group strictly requires that such cards should be provided to transport operators involved, who are also required to carry the card with the corresponding product while in transportation.