Water and Oil repellent / Adhesion control agent

MODIPER® F series

MODIPER® FS series

MODIPER® FP series

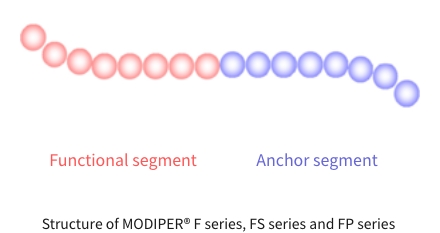

MODIPER® F series, FS series and FP series are innovative type block copolymers, which is

exclusively manufactured with NOF’s developed block polymer technology.

These 3 grades consist of `Functional segment' and `Anchor segment' as right figure, and they

can give some unique properties such as `Water and Oil repellent' , `Adhesion control' and more

as additives to coating or adhesive materials depending on kinds of Functional segment part.

Introduction of MODIPER® F series, FS series and FP series

- MODIPER® F series, FS series and FP series can improve surface properties of water repellency, anti-pollution property, anti-frictional property, tack strength control property and anti-cohesion property of acrylic coating materials or resins with 1-3% additive ratio.

- MODIPER® F series, FS series and FP series can be dissolved into various organic solvents and dispersable into acrylic polymers or synthetic resins.

- MODIPER® F series, FS series and FP series can make PTFE powder mix well into acrylic coating materials or resins

- MODIPER® F series, FS series and FP series do not contain PFOA (Perfluorooctanoic acid) material.

- MODIPER® F series, FS series and FP series do not affect the stability and thermal properties of base coating.

- MODIPER® FP series is the suitable additive for electric materials, because MODIPER® FP series doesn't have the silicone component which makes failure in contacting on electric parts.

Properties of MODIPER® F series, FS series and FP series

Lineup of MODIPER® F series, FS series and FP series

| Product name | Functional segment |

Anchor segment |

Solid content (wt.%) |

Solvent | Appearance | Property |

|---|---|---|---|---|---|---|

| MODIPER® F206 | Fluorinated copolymer |

Acrylic copolymer |

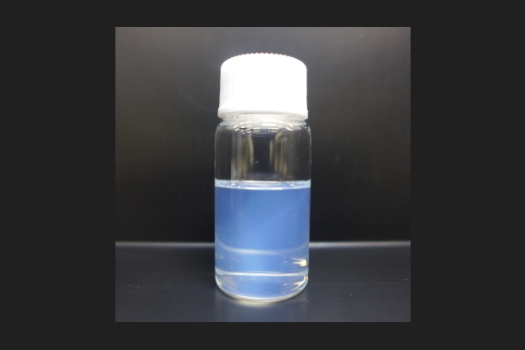

30 | MEK/MIBK | Blue-white transparent liquid | Adhesion control |

| MODIPER® F606 | 100 | - | White powder | Powder type of F206 | ||

| MODIPER® F246 | 30 | MEK/MIBM | Blue-white transparent liquid | Anti-Pollution | ||

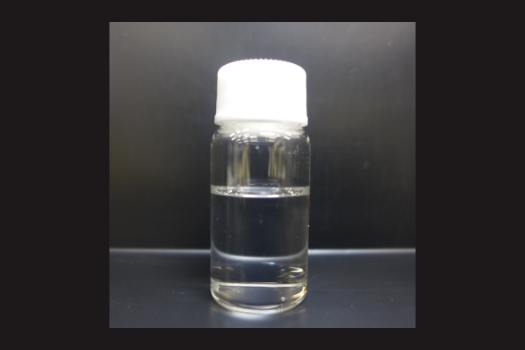

| MODIPER® F3636 | 30 | Paraffin solvent | Transparent liquid | Highly Water Repellency | ||

| MODIPER® F226 | 20 | IPA/Water | Blue-white transparent liquid | Environmentally friendly | ||

| MODIPER® FS710-1 | Silicone copolymer |

Acrylic copolymer |

15 | MEK/Toluene | Transparent liquid | Normal grade |

| MODIPER® FS700 | 100 | - | White powder | Powder type of FS710-1 | ||

| MODIPER® FS720 | 15 | MEK | Transparent liquid | Highly Water Repellency | ||

| MODIPER® FS730 | 30 | MEK | Transparent liquid | Anti-mar | ||

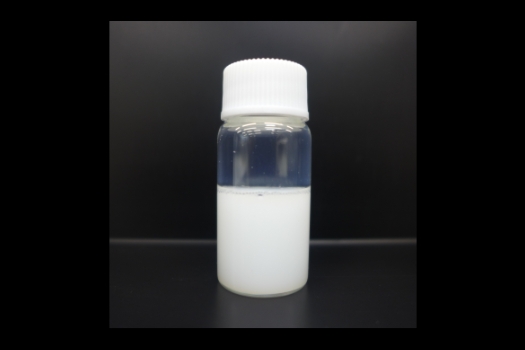

| MODIPER® FS770 | 15 | IPA/Water | White liquid | Environmentally friendly | ||

| MODIPER® FP100 | Non-Silicone copolymer |

Acrylic copolymer |

30 | Toluene/DMF | Blue-white transparent liquid | Adhesion control |

- MEK

- :Methyl Ethyl Ketone

- MIBK

- :Methyl Iso-butyl Ketone

- IPA

- :Isopropyl alcohol

- DMF

- :Dimethylformamide

Appearance of MODIPER® F series, FS series and FP series

Basic properties of MODIPER® F series

| Test item | Test method | Unit | F206 | F606 | F246 | F3636 | F226 | ||

|---|---|---|---|---|---|---|---|---|---|

| Viscosity | JIS K 7117 (1987) |

P | 0.3 | - | 0.3 | 0.1 | 0.7 | ||

| Hydroxyl value | JIS K 0070 (1992) |

mgKOH/g | 55 | 55 | 2 | 0 | 30 | ||

| Static contact angle 1) |

Water | JIS R 3257 (1999) |

Angle(°) | 110 | 110 | 110 | 110 | 115 | |

| n-Hexadecane | Angle(°) | 75 | 75 | 75 | 50 | 95 | |||

| Dynamic contact angle1) |

Water | Advance contact angle | Angle(°) | 120 | 120 | 120 | 125 | 110 | |

| Receding contact angle | Angle(°) | 65 | 65 | 65 | 90 | 20 | |||

| n-Hexadecane | Advance contact angle | Angle(°) | 70 | 70 | 70 | 80 | 80 | ||

| Receding contact angle | Angle(°) | 33 | 33 | 33 | 20 | 15 | |||

| Thermal properties |

TGA2) | 1% weight loss temperature | JIS K 7120 (1987) |

℃ | 170 | 170 | 170 | 235 | 165 |

| 5% weight loss temperature | 250 | 250 | 250 | 300 | 260 | ||||

- 1) test plaque:glass、solid content:10wt.%、dry condition:23℃×24h

- 2) Thermo Gravimetric Analysis(Rate of temperature rise: 10℃/min in a nitrogen atmosphere)

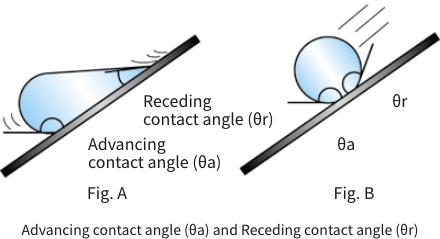

Dynamic contact angle

Dynamic contact angle consists of 2 type contact angle, Advancing contact angle (θa) and Receding contact angle (θr). In case the Receding contact angle (θr) shows low level as shown in Fig. A, the test liquid doesn't have good water and oil repellent level. On the other hand, in case the Receding contact angle (θr) shows low level as shown in Fig. B, the test liquid has excellent water and oil repellent level.

Basic properties of MODIPER® FS series

| Test item | Test method | Unit | FS710-1 | FS700 | FS720 | FS730 | FS770 | ||

|---|---|---|---|---|---|---|---|---|---|

| Viscosity | JIS K 7117 (1987) |

P | 0.1 | - | 0.1 | 0.1 | 0.5 | ||

| Hydroxyl value | JIS K 0070 (1992) |

mgKOH/g | 60 | 60 | 0 | 0 | 195 | ||

| Static contact angle1) |

Water | JIS R 3257 (1999) |

Angle(°) | 105 | 105 | 105 | 95 | 75 | |

| n-Hexadecane | Angle(°) | 20 | 10 | 20 | 25 | 25 | |||

| Thermal properties |

TGA2) | 1% weight loss temperature | JIS K 7120 (1987) |

℃ | 170 | 170 | 200 | 170 | 120 |

| 5% weight loss temperature | 190 | 190 | 240 | 210 | 230 | ||||

- 1) test plaque:glass、solid content:FS700→20wt.%、FS710-1, FS720, FS730→30wt.%、FS770→10wt.%、dry condition:23℃×24h

- 2) TGA:Thermo Gravimetric Analysis(Rate of temperature rise: 10℃/min in a nitrogen atmosphere)

Basic properties of MODIPER® FP series

| Product | Appearance | Solvent [wt%] | Solid content [wt%] | Viscosity [P] | Hydroxyl value [mgKOH/g] |

|---|---|---|---|---|---|

| MODIPER® FP100 | Light yellow transparent liquid | Toluene/DMF=60/40 | 30 | 0.4 | 27 |

Solubility of MODIPER® F series and FS series

| Solvent | F206 F606 |

F246 | F3636 | F226 | FS710-1 | FS700 | FS720 | FS730 | FS770 |

|---|---|---|---|---|---|---|---|---|---|

| Acetone | ✔ | ✔ | × | ✔ | ✔ | ✔ | ✔ | ✔ | ✔- |

| Methyl Ethyl Ketone | ✔ | ✔ | × | ✔ | ✔ | ✔ | ✔ | ✔ | × |

| Methyl Iso-butyl Ketone | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | × |

| Ethyl Acetate | ✔ | ✔ | × | ✔ | ✔ | ✔ | ✔ | ✔ | × |

| Butyl Acetate | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | × |

| Tetrahydrofuran | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔- |

| Methanol | × | × | × | × | × | × | × | × | ✔- |

| Ethanol | ✔- | ✔- | × | ✔- | ✔ | ✔- | ✔- | × | ✔ |

| n-Butanol | × | ✔ | × | ✔- | ✔ | × | ✔ | ✔- | × |

| Ethylene Glycol Monomethyl Ether |

✔ | ✔ | × | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Ethylene Glycol Monoethyl Ether |

✔ | ✔ | × | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| n-Hexane | × | × | ✔ | × | ✔- | × | ✔- | ✔- | × |

| Toluene | × | ✔- | ✔ | ✔- | ✔ | ✔ | ✔ | ✔ | × |

| Xylene | × | ✔- | ✔ | ✔- | ✔ | × | ✔ | ✔ | × |

| Dimethylformamide | ✔ | ✔ | × | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Chloroform | ✔ | ✔ | ✔ | ✔- | ✔ | ✔ | ✔ | ✔ | × |