Anti-pollution

Improving anti-pollution property of Unsaturated Polyester resins with MODIPER® F246

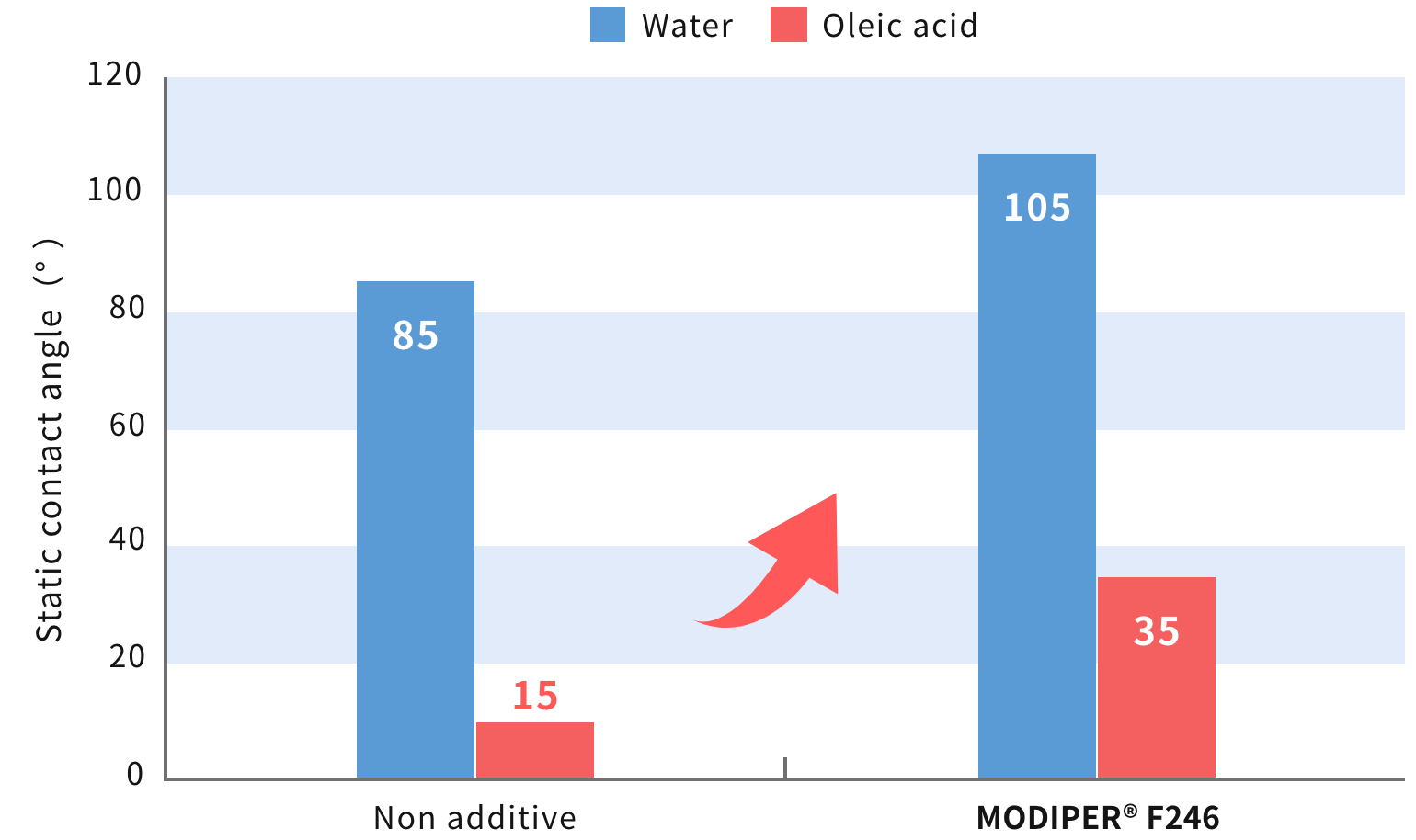

Water and Oil repellent of Unsaturated Polyester resins can be improved with adding MODIPER®

F246.

Consequently, water stains and oil stains can be removed easily.

Preparation of test plaque

■ Composition

| material | Compound | Formulas (part by weight) |

|---|---|---|

| Resin | Unsaturated polyester resin | 70 |

| Low Profile additive | Polystyrene 1) | 30 |

| Inorganic filler | Calcium Carbonate | 160 |

| Release agent | Zinc Stearate | 4 |

| Thickener | Magnesium Oxide | 2 |

| Curing agent | PERHEXYL A 2) | 1.4 |

| Retarder | Benzoquinone 3) | 1 |

| Anti-pollution agent 4) | MODIPER® F246 | 2 |

| Reinforcing material | Glass fiber | 28 |

- 1) 30wt.% styrene solution

- 2) t-hexyl peroxyacetate of NOF CORPORATION

- 3) 5wt.% diethylene glycol solution

- 4) weight of active element

■ Aging condition

- ・Condition : 40℃×24h

■ Molding condition

- ・Equipment : Compression molding machine

- ・Mold temperature : Upper/Lower=140℃/130℃

- ・Pressure : 10MPa

- ・Curing time : 5min

Test method and criteria

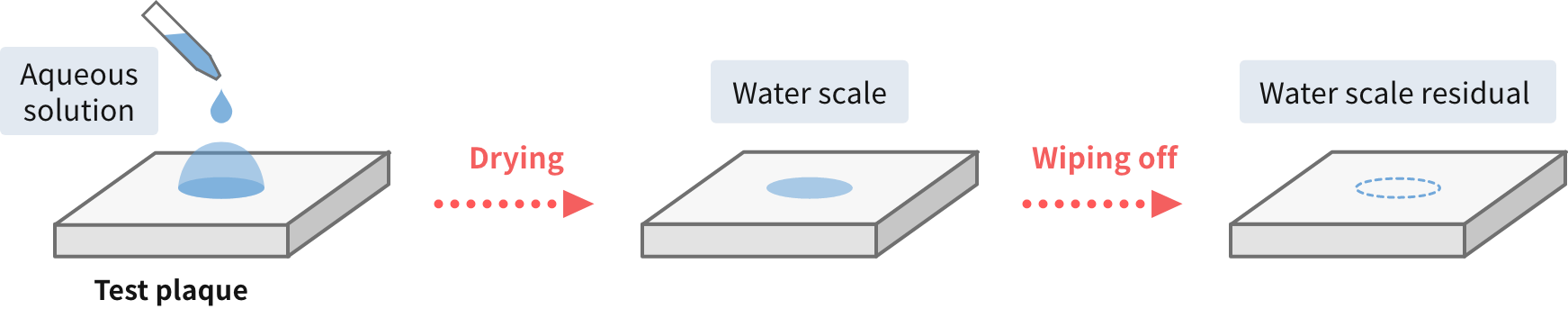

Anti-pollution property was evaluated from residual rate of water scale after wiping off the scale which was simply created with aqueous solution containing pigment.

- ・Testing standard : static contact angle measurement (JIS R 3257 (1999))

- ・Test device : contact angle meter Drop Master 500 (Kyowa interface science Co., Ltd.)

- ・Procedure : measure the contact angle 30sec after dropping water or solvent on surface.

- ・Test solvent : Water, Oleic acid

Test result

Static contact angle was improved with adding MODIPER® F246, and Anti-pollution property was also improved consequently.