Product information

- TOP

- Business

- Functional Chemicals & Polymers

- Blocked Carboxylic acid / Functional sealing / coating material

Blocked carboxylic acid related products

-

Blocked carboxylic acid related products

-

Blocked carboxylic acid is a compound with a latent carboxyl group.Blocked carboxylic acid generates carboxylic acid by thermal dissociation of blocked agent.

Introduction of Blocked Carboxylic acid(656KB)

Blocked Acid Hardening Technique

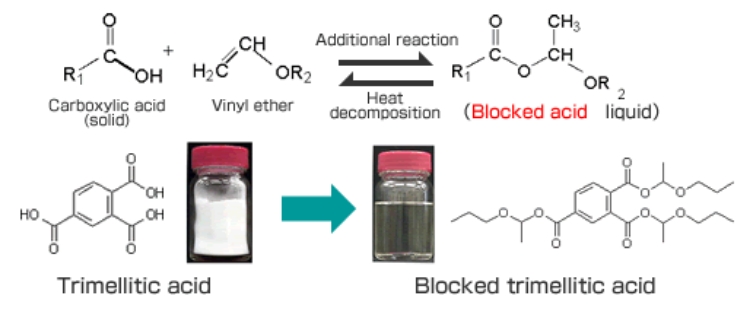

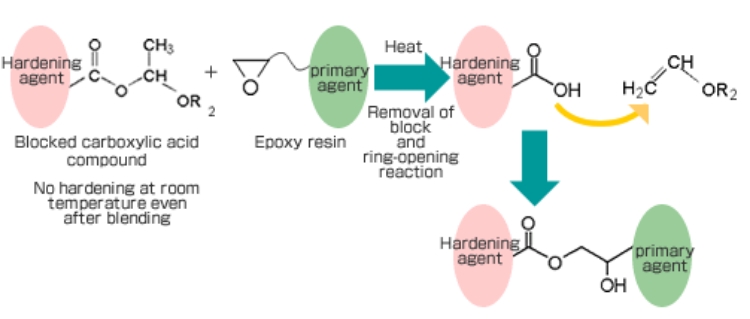

What is the blocked carboxylic acid technique?

By using a vinyl ether to block (protect) an organic compound containing carboxylic acid, which is normally a solid powder:

・The solid can be turned into a liquid, which makes it easier to blend and improves its solubility

・Heating removes the protective base (vinyl ether), thus restraining the activity of carboxylic acid (so that it can be used when needed)

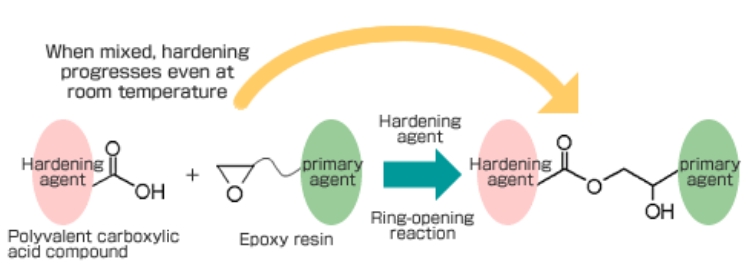

A hardening technique for epoxy resin that uses blocked carboxylic acid

(1) What is epoxy resin?

More than 100,000 tons of epoxy resin is used annually worldwide in coatings, electrical and electronic devices, civil engineering, adhesives, and many other applications. A compound using carboxylic acid is employed as the hardening agent. The main drawback is the difficulty of handling this agent because it is a solid powder. Furthermore, mixing carboxylic acid and epoxy resin causes a chemical reaction that prevents the long-term stability of work processes.

(2) Why use blocked carboxylic acid?

When blocked carboxylic acid is used as a hardening agent, the epoxy resin remains a liquid at room temperature. This is because the chemical reaction with the epoxy group does not start after blending as the carboxylic acid is protected. Only when the mixture is heated to the point where the blocked vinyl ether is released (well over 100oC), does the chemical reaction between the carboxylic acid and epoxy group begin and hardening take place.

Blocked carboxylic acid ∼Property∼

Product name Carboxylic acid Active ingredient(wt%) Solvent Viscosity3)(mPa・s) Acid equivalent4)(g/mol) De-blocking temperature(degree) NOFCURE®TN-1 Trimellitic acid 60 PGMEA1) 7 260 134 NOFCURE®TN-2 Aliphatic modified carboxylic acid 67 Aromatic hydrocarbon 30 420 >170 NOFCURE®TN-5 Trimellitic acid 60 PGMEA1) 6 260 129 NOFCURE®TN-6 Pyromellitic acid 60 PGMEA1) 7 250 117 SANTACID®D-2 Aliphatic modified carboxylic acid 77 Butyl diglyme2)

Divinyl ether17,000 385 208 SANTACID®G Glutaric acid 91 Divinyl ether 4,000 150 221 1) 2-Acetoxy-1-methoxy propane (CAS registry No.:108-65-6, Boiling point:146 degrees))

2) Diethylene glycol dibutyl ether (CAS registry No.:112-73-2, Boiling point:256℃)

3) Measurement temperature:25℃

4) Acid equivalent weight is the product's value. (Including solvent)

® : Registered Trademark of NOF CORPORATION in Japan.

Functional sealing / coating material

-

Functional sealing / coating material

-

We are developing functional materials by utilizing NOFs developing and product design technology which was cultivated in a long years of experience in the electronic materials field.

【Functional sealing material 】

・Sealing material for film liquid crystal and PDLC type light control film【Functional coating material】

・Strippable coating materialFunctional sealing material

Functional sealing material

We are developing functional sealing materials by utilizing NOF's material development and product design technology.

【 Features 】

· Control of UV / heat-curability

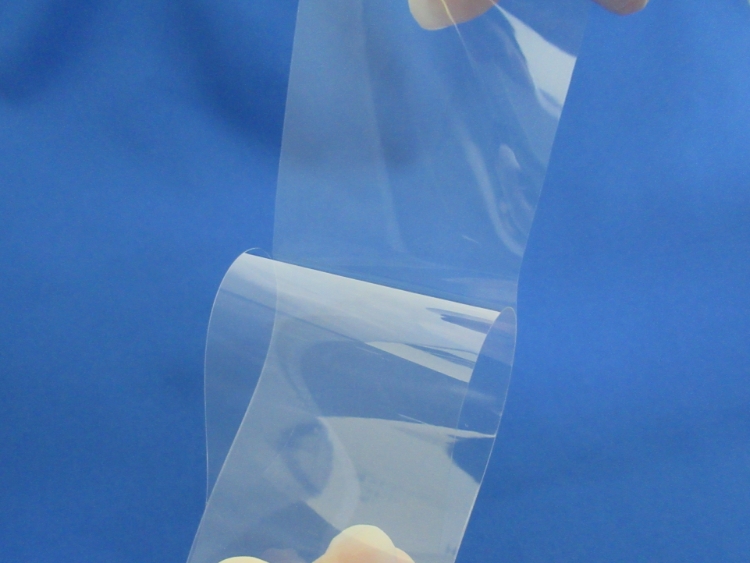

·High flexibility applicable to flexible substrates

·High adhesion property to flexible substrates

·High barrier property

By using our sealing material for flexible liquid crystal film and sealing material for PDLC type light control film, it is possible to prevent display defects and improve reliability of the device.

【Application example】

·Sealing material for flexible liquid crystal film and PDLC type light control filmFunctional coating material

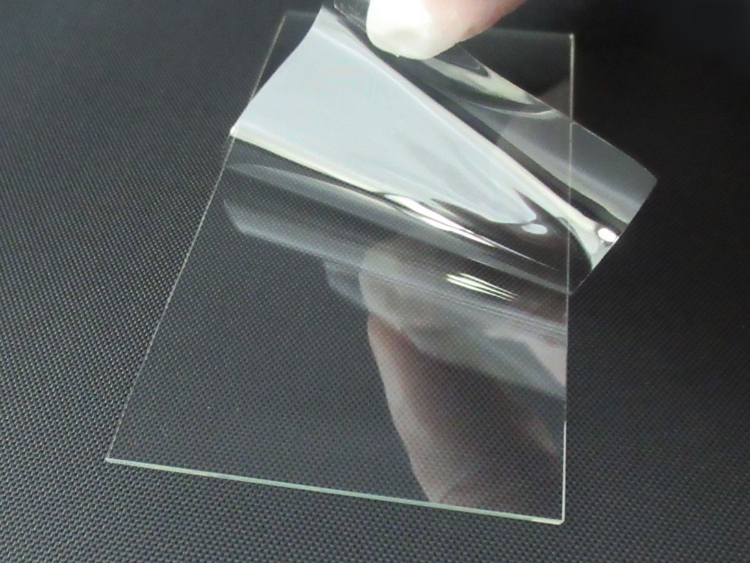

Our functional coating material is "coatable type"material which can form a protective film. Protective film can be formed by coating and UV-curing our material to the place you prefer to protect. Furthermore, this protective film can be easily strip after protection use.

【 Features 】

·Transparent protective film for temporary process protection

· Transparent protective film for temporary process protection

This "coatable type" material can be formed to substrates with curved surface, which the traditional "Film bonding type" protect film is weak at.It is also suitable for temporary protection of products that require optical inspection because of its transparentcy. In addition, the protective film is easily strippable and doesn't contaminate the substrate.

【Application example】

PET Film

Glass