Functional additives

MODIPER® A series

MODIPER® C series

MODIPER® C series

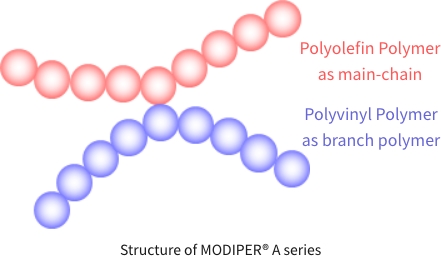

MODIPER® A, C series are innovative type graft copolymers, consisting of polyolefin as main-chain and polyvinyl as branch polymer, which is exclusively manufactured by NOF CORPORATION utilizing NOF’s developed grafting technology. MODIPER® A, C series can improve the mechanical property, surface property, compatibility and others of thermoplastic resins.

About MODIPER® A, C series

- MODIPER® A series is a graft copolymer, consisting of polyolefin as main-chain and polyvinyl as branch polymer.

- MODIPER® C series is a graft copolymer, consisting of polycarbonate as main-chain and polyvinyl as branch polymer.

- MODIPER® A, C series can improve the mechanical property, surface property, compatibility and others of thermoplastic resins with 1-10% additive ratio.

- MODIPER® A, C series are additives with high molecular weight, so they can keep the mechanical, thermal, molding properties of any resins. Furthermore, they do not also cause migration and evaporation from the resin.

- MODIPER® A, C series are environmental friendly, because no halogen compounds are contained.

Properties of MODIPER® A, C series

Lineup of MODIPER® A, C series

| Product name | Composition | Appearance | CAS No. | |

|---|---|---|---|---|

| Main chain polymer | Branch polymer | |||

| MODIPER® A1100 | PE | PS | White Pellet | 106826-12-4 |

| MODIPER® A1401 | AS | Slight yellowish Pellet | 106826-13-5 | |

| MODIPER® A3400 | PP | AS | Slight yellowish Pellet | 115180-57-9 |

| MODIPER® A4100 | EGMA | PS | White Pellet | 117091-81-3 |

| MODIPER® A4300 | P(BA/MMA) | White Pellet | 118497-17-9 | |

| MODIPER® A4400 | AS | Slight yellowish Pellet | 118497-09-9 | |

| MODIPER® A5300 | EEA | P(BA/MMA) | White Pellet | 118497-18-0 |

| MODIPER® A5400 | AS | Slight yellowish Pellet | 118497-12-4 | |

| MODIPER® CL130D | PC | PS | White Pellet | 1470303-78-6 |

| MODIPER® CL430-G | P(GMA/AS) | White Pellet | 103598-77-2 | |

- PE

- Polyethylene

- PP

- Polypropylene

- EGMA

- Ethylene-Glycidyl Methacrylate copolymer

- EEA

- Ethylene-Ethyl Acrylate copolymer

- PC

- Polycarbonate

- PS

- Polystyrene

- AS

- Acrylonitrile-Styrene copolymer

- P(BA/MMA)

- Buthyl Acrylate-Methyl Methacrylate

- P(GMA/AS)

- Glycidyl Methacrylate-Acrylonitrile-Styrene copolymer

Appearance of MODIPER® A, C series

Basic properties of MODIPER® A, C series

| Test item | Test method | Unit | MODIPER® A series | MODIPER® C series |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1100 | A1401 | A3400 | A4100 | A4300 | A4400 | A5300 | A5400 | A6600 | CL 130D |

CL 430-G |

|||||

| Mechanical properties | Tensile | Strength | ISO 527-1 (JIS K 7161) |

MPa | 15 | 17 | 30 | 14 | 6 | 13 | 6 | 10 | 8 | 55 | 73 |

| Elongation | % | 60 | 20 | 10 | 60 | 120 | 80 | 120 | 280 | >400 | 5 | 10 | |||

| Flexural | Strength | ISO 178 (JIS K 7171) |

MPa | 14 | 19 | 45 | - | - | - | - | - | - | 78 | 97 | |

| Elongation | MPa | 400 | 600 | 1700 | - | - | - | - | - | - | 2200 | 2300 | |||

| Izod impact(notched specimen) | ISO 180 (JIS K 7110) |

kJ/m2 | 26 | 4.3 | 1.8 | N.B | N.B | N.B | N.B | N.B | N.B | 1.1 | 3.1 | ||

| MFR1) | ISO 1133 (JIS K 7210) |

g/10min | 1.2 | 0.9 | 6 | 0.7 | 0.1 | 0.3 | 0.1 | 1.3 | 1 | 13 | 5 | ||

| Thermal properties | TGA2) | 1% weight loss temperature | JIS K 7120 | ℃ | 337 | 306 | 302 | 308 | 282 | 291 | 279 | 317 | 233 | 270 | 260 |

| 5% weight loss temperature | 397 | 371 | 375 | 381 | 354 | 384 | 357 | 386 | 320 | 337 | 352 | ||||

| DSC3) | Melting temperature | JIS K 7121 | ℃ | 111 | 110 | 165 | 97 | 98 | 100 | 97 | 97 | 71 | - | - | |

| DMA4) | Glass temperature |

ISO 6721 (JIS K 7244) |

℃ | 85 | 90 | 110 | 0 | -0 | -10 | 0 | -25 | -30 | 110 | 100 | |

- 1) 230℃(CL130D、CL430-G)、190℃(Others)、2.16kgf

- 2) Thermo Gravimetric Analysis: Rate of temperature rise: 10℃/min (in a nitrogen atmosphere)

- 3) Differential Scanning Calorimetry: Rate of temperature rise: 10℃/min (in a nitrogen atmosphere)

- 4) Dynamic Mechanical Analysis;Mode: Tension mode, Frequency: 1Hz, Rate of temperature rise: 10℃/min (in a nitrogen atmosphere)

- 5) N.B:Not Break

Performances of MODIPER® A, C series

MODIPER® A, C series can add some properties to resins depending on the resin type with 1-10% additive ratio.

| Property | MODIPER grade | Resin | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PE | PP | ABS | PMMA | PLA | POM | PA | PET | PBT | PC | mPPE | PPS | TPO | |||

| Tribological properties improve | A1100 | ✔ | ✔+ | ✔+ | ✔ | ✔ | ✔ | ✔ | |||||||

| A1401 | ✔ | ✔+ | ✔+ | ✔ | ✔ | ✔ | ✔ | ||||||||

| A4100 | ✔ | ✔ | |||||||||||||

| Scratch properties improve | A1100 | ✔ | ✔ | ✔ | |||||||||||

| A1401 | ✔ | ✔ | ✔ | ||||||||||||

| Impact properties improve | A4300 | ✔ | ✔ | ✔+ | ✔+ | ✔ | |||||||||

| A4400 | ✔ | ✔+ | ✔+ | ✔+ | |||||||||||

| Thermal shock improve | A5300 | ✔ | ✔+ | ✔+ | ✔ | ||||||||||

| Paintability improve | A3400 | ✔ | |||||||||||||

| A5400 | ✔ | ✔ | |||||||||||||

| A6600 | ✔ | ||||||||||||||

| Melt flow properties improve | A1100 | ✔ | |||||||||||||

| A3400 | ✔ | ✔+ | ✔ | ✔ | |||||||||||

| CL130D | ✔+ | ||||||||||||||

| Organic filler dispersibilities improve | A4100 | ✔ | ✔ | ✔+ | ✔ | ✔ | |||||||||

| Inorganic filler dispersibilities improve | A4300 | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||||

| CL430-G | ✔+ | ||||||||||||||

| Chemical resistance improve | A3400 | ✔+ | |||||||||||||

| Matting | A4400 | ✔ | ✔+ | ||||||||||||

✔+:Excellent performance

✔:Good performance

- PE

- Polyethylene

- PP

- Polypropylene

- ABS

- Acrylonitrile butadiene styrene

- PMMA

- Poly(methyl methacrylate)

- PLA

- Polylactic acid

- POM

- Polyacetal

- PA

- Polyamide

- PET

- Polyethylene terephthalate

- PBT

- Polybutylene terephthalate

- PC

- Polycarbonate

- mPPE

- modified-Polyphenyleneether

- PPS

- Polyphenylenesulfide

- TPO

- Thermoplastic polyolefin