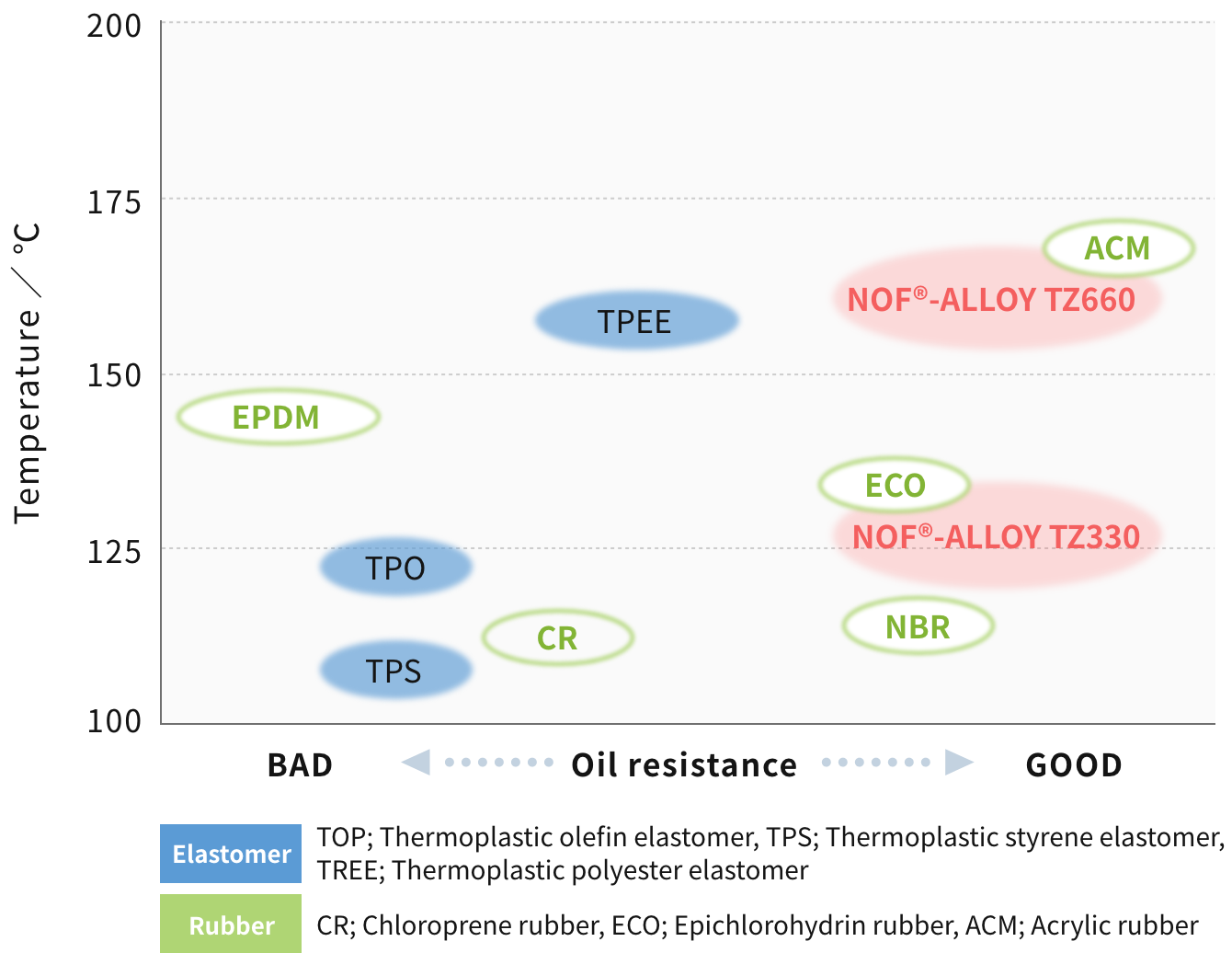

Oil resistance / Heat resistance

Oil resistance and Heat resistance of NOF®-ALLOY TZ series

NOF®-ALLOY TZ series has excellent oil resistance and heat resistance, because NOF®-ALLOY TZ series

contains acrylic rubber as one of the main components.

NOF®-ALLOY TZ series consists of two

types, NOF®-ALLOY TZ330 as standard grade and NOF®-ALLOY TZ660 as high heat resistant grade, and

these grades can be used at maximum 120℃ and 150℃, respectively.

Test results of Oil resistance

NOF®-ALLOY TZ series shows excellent oil resistance as results of oil resistance test in IRM 903 oil at 120℃ or 150℃ for 120h.

Physical property change of NOF®-ALLOY TZ330 series after oil resistance test (120℃)

| Sample | 120℃ x 120h | |||

|---|---|---|---|---|

| Strength change ratio % | Elongation change ratio % | Hardness change point | Weight change ratio % | |

| NOF®-ALLOY TZ330-6511-BK | -52 | -31 | -19 | 41 |

| NOF®-ALLOY TZ330-7511-BK | -28 | -27 | -13 | 15 |

| TPO | -49 | -29 | -18 | 66 |

| EPDM | -73 | -44 | -52 | 144 |

Physical property change of NOF®-ALLOY TZ660 series after oil resistance test (150℃)

| Sample | 150℃ x 120h | |||

|---|---|---|---|---|

| Strength change ratio % | Elongation change ratio % | Hardness change point | Weight change ratio % | |

| NOF®-ALLOY TZ660-7612-BK | -12 | 4 | -2 | 5 |

| TPEE | -34 | -30 | -19 | 28 |

| EPDM | -81 | -40 | -59 | 184 |

Test results of Heat resistance

NOF®-ALLOY TZ series shows excellent hear resistance as results of heat resistance test at 120℃ or 150℃ for 120h.

Physical property change of NOF®-ALLOY TZ 330 series after heat resistance test (120℃)

| Sample | 120℃ x 120h | |||

|---|---|---|---|---|

| Strength change ratio % | Elongation change ratio % | Hardness change point | Weight change ratio % | |

| NOF®-ALLOY TZ330-6511-BK | 4 | -4 | -1 | -4 |

| NOF®-ALLOY TZ330-7511-BK | 14 | -19 | 0 | -7 |

| TPO | -9 | -14 | 4 | -2 |

| EPDM | 25 | -45 | 7 | 0 |

Physical property change of NOF®-ALLOY TZ660 series after heat resistance test (150℃)

| Sample | 150℃ x 120h | |||

|---|---|---|---|---|

| Strength change ratio % | Elongation change ratio % | Hardness change point | Weight change ratio % | |

| NOF®-ALLOY TZ600-7612-BK | 22 | 24 | 1 | -4 |

| TPEE | 17 | -5 | 9 | -2 |

| EPDM | 17 | -76 | 17 | -1 |