Anti-scratch

Test condition

-

① Evaluation of Anti-scratch property

-

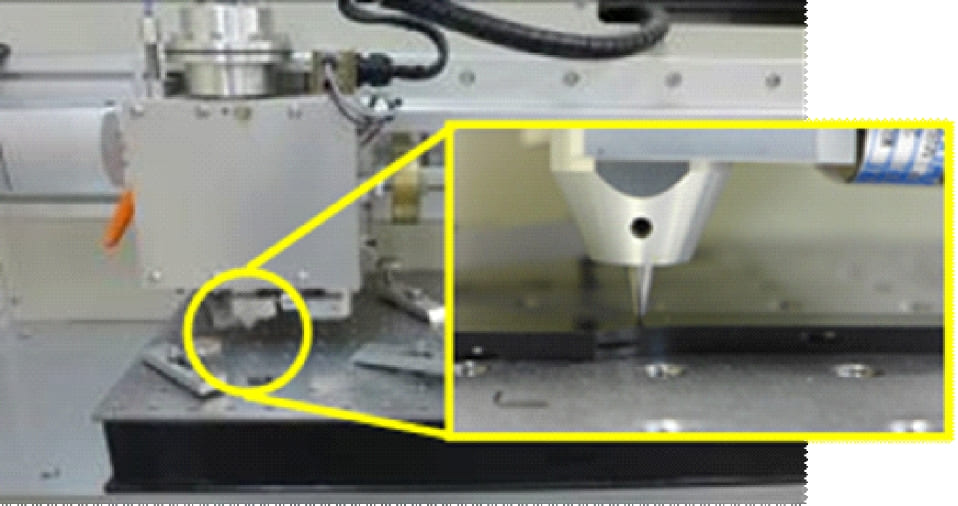

■ Test equipment

Scratch tester KK-01 (KATO TECH Co., Ltd.)

Fig. Scratch tester KK-01 -

■ Evaluation condition (ISO 19252 (ASTM D7027-05))

- ・Incremental load : 1-15N or 1-30N

- ・Scratch velocity : 100mm/s

- ・Scratch distance : 100m

- ・Tip size : φ=1.0 (Stainless steel ball)

-

■ Evaluation

The value of anti-scratch property is shown as the load that the initial scratch mark was observed on the surface.

It is preferred that scratch load is large.

-

-

② Evaluation of anti-mar property

-

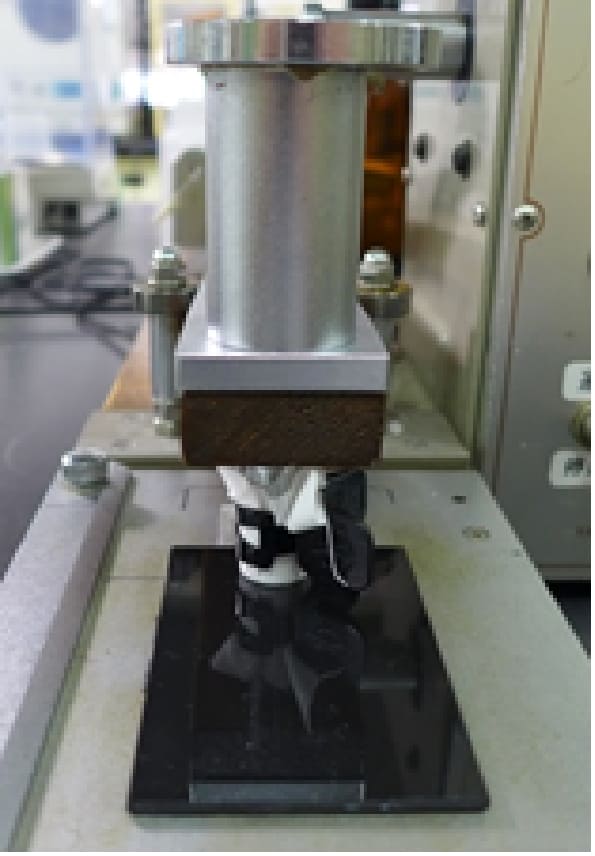

■ Test equipment

NO416-TMI CROCK METER (YASUDA SEIKI SEISAKUSHO, LTD.)

Fig. NO416-TMI CROCK METER -

■ Evaluation condition

- ・Load : 1kgf

- ・Velocity : 200 mm/s

- ・Round : 100 times

- ・Counter material : Cotton cloth

-

■ Evaluation

Gloss retention is calculated from initial and after tested gloss.

-

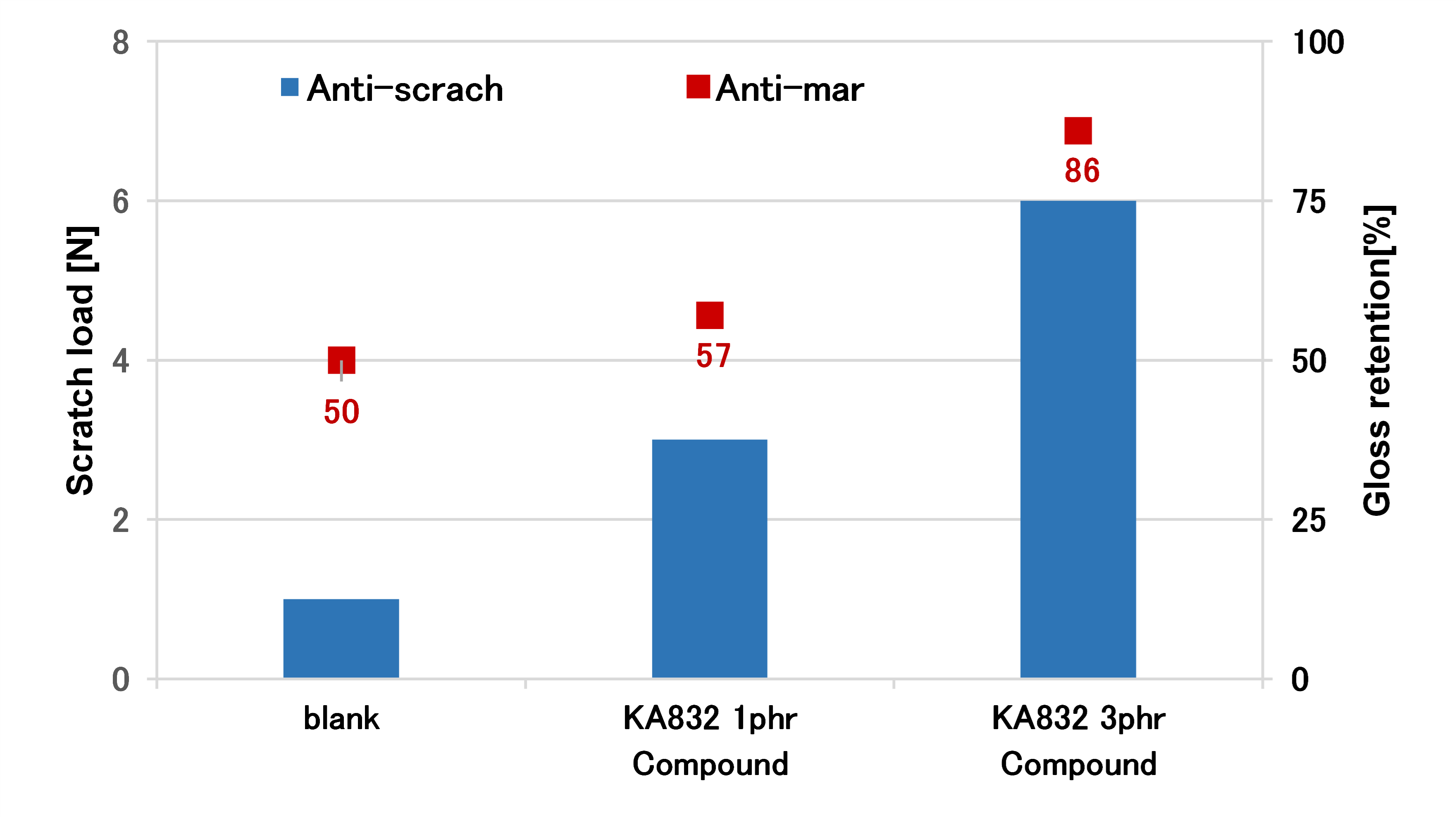

Test results

NOF®-ALLOY KA series can improve the anti-scratch property as well as anti-mar property.

-

*PP compound: b-PP/EPR/Talc=70/10/20 wt%

Fig. Evaluation of Anti-scratch property of NOF®-ALLOY KA series